3D printed anti-fog protection, made out of recycled face masks

Objectives:

- 3D printing & Injection molding

- Recycling & Sustainability

- Ergonomics

Design Challenge

The challenge in this context is to develop a sustainable solution for the growing volume of coronavirus-related waste generated during the COVID-19 pandemic. The goal is to recycle this waste and create a valuable, functional product that can be reintegrated into the pandemic response cycle. By recycling this corona-related waste, this project wants to address environmental responsibility.

Solution

During the onset of the COVID-19 pandemic, the surge in waste from disposable items such as face masks, gloves, and hand sanitizer bottles became a significant environmental concern. Media reports highlighted the widespread issue of discarded masks polluting streets and natural environments. It was soon discovered that disposable face masks, being made of plastic, had the potential for recycling. Simultaneously, another pressing issue emerged: the fogging of glasses caused by mask-wearing, a problem experienced by many.

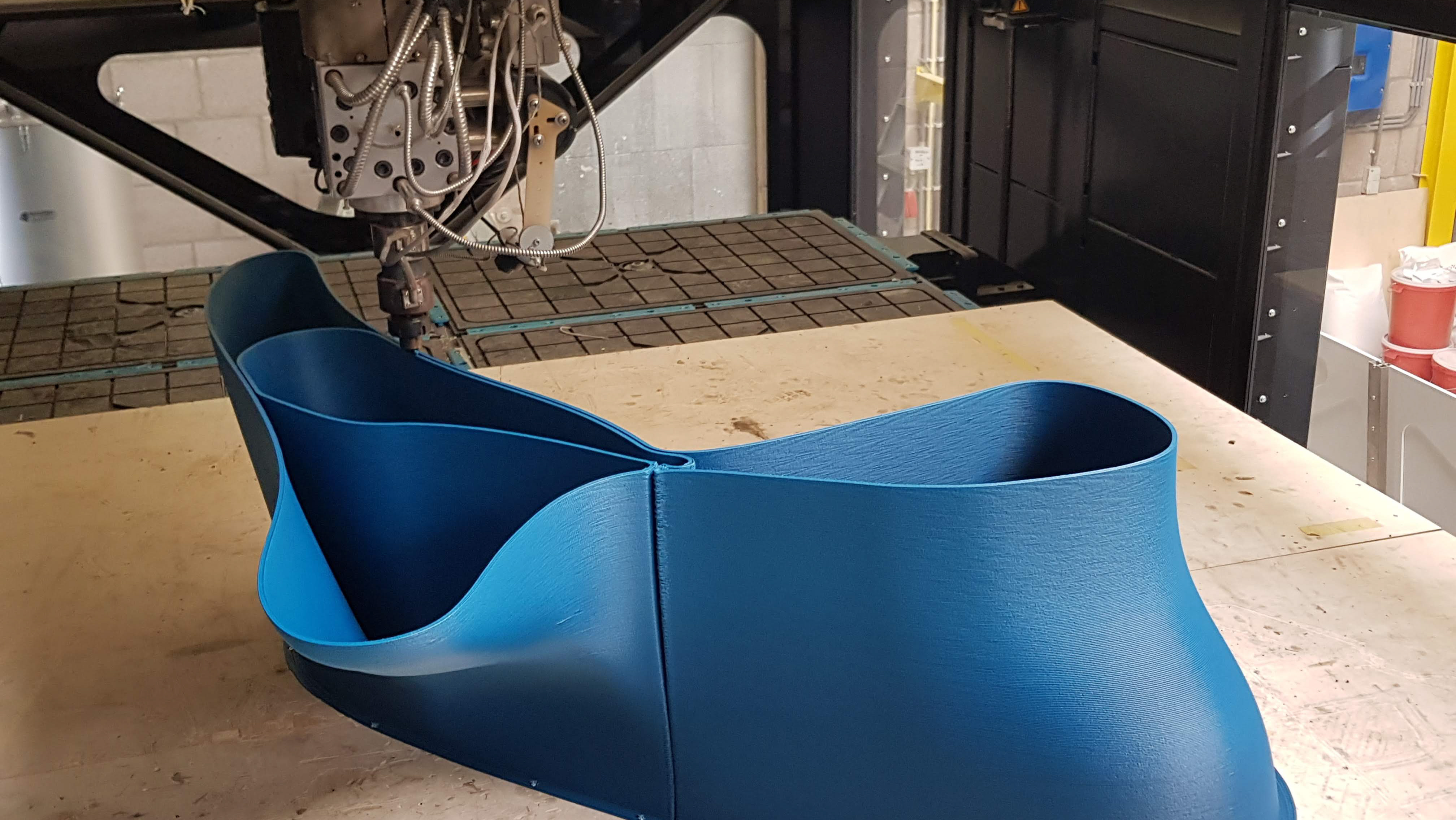

In response to these challenges, a design project was developed to recycle disposable face masks and repurpose them into a practical solution. A campaign was launched to collect used masks, which were then thoroughly sanitized to eliminate any potential bacteria or viruses. Using various processing techniques, the masks were transformed into granulate material, which was molded into specific shapes through 3D printing and injection molding processes.

This initiative resulted in the creation of the Anti-Fog Tool, designed to prevent fogging on glasses. Through a series of prototypes, the design was optimized for ergonomic fit, ease of cleaning, and reusability. Most notably, the product is made entirely from recycled disposable face masks, addressing both environmental waste and a common inconvenience faced during the pandemic.

Process

Specs of final design

Final design

Video

This work was published in the Dutch trade journal Constructeur. You can find the article on page 25 of Constructeur, Issue 3, 2021.