Step count physicalization to motivate students to walk more.

Objectives:

- FDM 3D printing

- Health & Vitality

- Behaviour change

Design Challenge

This design challenge aims to design a motivating environment for vitality and sports. Here, an interactive system or service must be designed through data physicalization in public spaces. This could be on the TU/e campus or in parks. The designed artifact needs to motivate people to be more physically active during their days.

Solution

Steptagon is a public interaction model that connects to your health data and shows your step count per week. It aims to motivate students on TU/e campus to have sufficient physical activity through walking. If students walk ten thousand steps a day and reach this goal at least 4 times a week, they can get a free drink. The earned coupon can be redeemed in the catering center on campus by using the barcode in the Steptagon app.

Students not only compare physical activities with themselves but compare with peers because multiple Steptagon are placed in public spaces.

Students not only compare physical activities with themselves but compare with peers because multiple Steptagon are placed in public spaces.

Video

Design Process

The project is divided into three main iterations. Iteration 1 is from the design brief until the first prototype (named 'MIDTERM'). Iteration 2 is about creating new perspectives by creating two different concepts, and iteration 3 is about developing a final artifact, together with a business aspect.

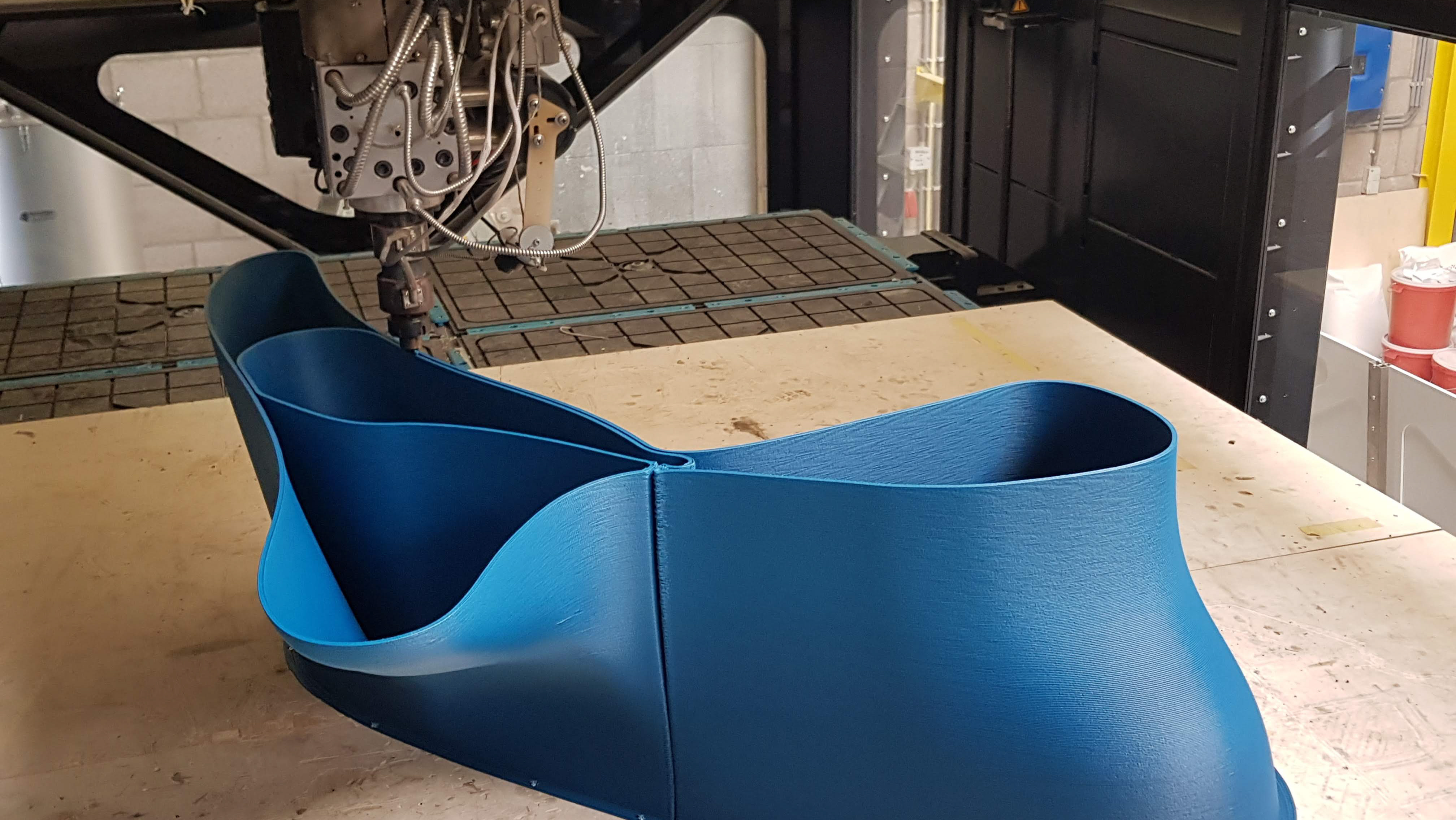

Breakthrough - 3D print experimentations

Human-Computer Interaction (HCI) principles were utilized to facilitate this interaction, given the current emphasis on expressivity within the field. Achieving meaningful user-artifact interactions requires a focus on both tangibility and aesthetics. The Aesthetics of Interaction (AoI) are critical for understanding the tactile experiences associated with the artifact, as touch is primarily mediated through the hands. This approach enables the creation of physical, tangible interactions with data through the artifact.

To emphasize tangibility, a material exploration was undertaken, leading to the integration of 3D printing on fabrics.

3D printing on mesh

Mesh experiment

3D printing on velvet

Velvet experiment

During the experimentation process, 3D printing with TPU on various fabrics was explored to enhance the artifact's tangibility. The most significant breakthrough occurred when two different fabrics were incorporated into a single print job, with the filament serving to attach them. This technique was subsequently used to create a button in the final artifact.

Overviews

3D print experimentations on fabrics

Technical overview